The formulation of a safe, effective COVID-19 vaccine is one thing, but its distribution to potentially billions of recipients is quite another. Make no mistake, transportation at sucha scale will entail a complex logistical operation, a consequence of the ultra-low storage temperatures required to preserve each and every dose.

As the life-saving vaccine journeys by land, sea and air from laboratories to distribution centres - and then onward to clinics, pharmacies and hospitals - the deep-freeze delivery chain, also known as the "ultra cold chain" will shoulder the burden of optimizing conditions. The stakes couldn't be higher - the prevention of millions of deaths and the reopening of society ultimately depends on their success.

These cold, hard facts make the release of a new product by supply chain analytics startup Logmore a cause for celebration.

Low Temperature, High Risk

While the Moderna vaccine requires storage at -20°C, the Pfizer/BioNTech vaccine, of which 50 million doses were planned to be produced in 2020 and up to 1.3 billion in 2021, cannot be removed from a temperature of -70°C, or -94°F. To put this in perspective, this is far lower than the Antarctic winter, let alone the level that can be reached by a typical home freezer.

"Vaccines lose effectiveness and their potency if they're exposed to temperatures outside of the range that they're supposed to be kept in," admits Michelle Seidel, UNICEF's immunization supply chain specialist. UNICEF is currently mapping out a network of specialized cold-storage units running on solar power for use in the developing world, and there are countless initiatives tackling challenges from all angles.

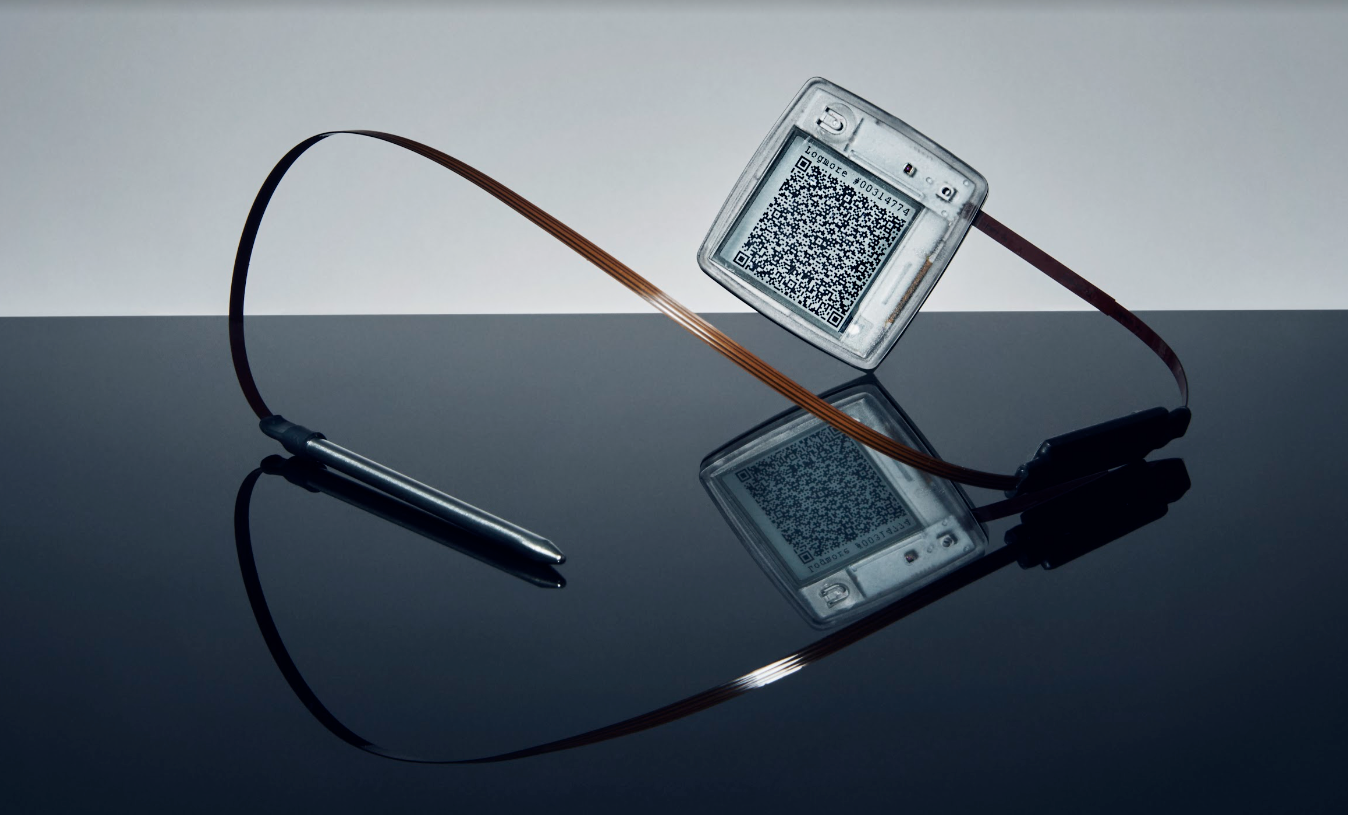

Finnish startup Logmore is one company to design a solution that facilitates safer shipping. The firm's latest high-tech product, Logmore Dry Ice, is built to withstand temperatures as low as -100°C and uses calibrated sensors to monitor cargo with complete accuracy.

Carriers can connect the solution to their company systems and use it to track temperature, humidity, light, shocks, and location. Thanks to a novel QR code data-logger that syncs with the cloud using any smartphone camera, information can be tracked in real-time, with alerts notifying users if temperatures get too high.

Needless to say, quality assurance is critical if the public's fears about a vaccine developed at warp speed are to be assuaged. The percentage of Americans who say they would get vaccinated for the coronavirus has sharply declined since earlier this year.

Often, it's the "last mile" of the supply chain where so many snafus can take place. At one local clinic in Finland, a nurse received an alert from Logmore's system that a batch of vaccines had crossed the critical temperature threshold before arrival in mid-January, and her team was able to ensure that enough people came to receive injections before any spoilage took place. Without Logmore's solution having been in place, the clinic may have simply put the batch into their own deep freezers, none the wiser.

"In general things are going really well, but from my perspective, looking at the industry, the challenges relate to end-to-end visibility and transparency," Logmore COO Niko Polvinen recently told the Techday Network.

"Supply chains are often really complicated, as there are multiple operators - a plane takes the shipment from A to B, but from there, you need to take a truck, then you may need some warehousing and all that. Often there are different companies managing these different stages in the supply chain, and combining the information of all of these phases is really challenging.

"Often, companies use different temperature monitoring systems, and the data isn't combined into any holistic view."

The Most Complex Logistics Operation in History

The rollout of Logmore Dry Ice couldn't come at a better time, as several temperature-sensitive vaccines have received emergency regulatory approval in order to initiate distribution. In the meantime, Logmore has been working hard towards securing partnerships with global shipping concerns and recently announced an alliance with French cold chain packaging firm Sofrigam.

Logmore's novel logger tag product works with existing infrastructure, enabling vaccine manufacturers to verify product status and collect measurements in the blink of an eye. Fast, reliable deployment is certain to be a critical issue in the months ahead.

"The world has never ever seen anything like this - in this much volume, especially this dry ice, extreme cold shipments. It's hundreds and hundreds of times larger than anything done before," Polvinen said.

Products of this nature are essential for preserving such a sensitive vaccine as it makes its way around the globe. And the challenges don't stop at temperature control; substandard transport infrastructure in certain parts of the world is likely to pose more problems, so too adverse weather conditions and disrupted flight paths.

One organization under no illusions about the challenges ahead is the International Air Transport Association (IATA), which conceded that we are facing "the largest and most complex global logistics operation ever undertaken." Little wonder Pfizer is spending $2 billion to create its own direct distribution network.

In its guidance published on November 16, the IATA makes a cogent point regarding the need to "define the roles and responsibilities of parties involved in the distribution of vaccines, particularly government authorities and NGOs, to assist safe, fast and equitable distribution as broadly as possible."

We are not a One World State: these roles and responsibilities will need to be judiciously determined, and vast resources allocated to ensure that hiccups do not occur along the way. Hiccups that could include delivery bottlenecks and delays due to sluggish clearance at customs.

Although most prior vaccines have not required such excessively low temperatures to remain viable, the amount of wastage due to problems such as heat exposure, breakage and poor stock management is deeply concerning. In a paper published last year, the World Health Organization claimed wastage rates depend on vial presentation, with 5% waste for single dose and up to 50% for 20-dose shipments.

The wastage rate for two doses - which is required by the Pfizer and Moderna vaccines - is 10%. Hundreds of millions of dollars' worth of vaccine could well go to waste, making the implementation of solutions like Logmore Dry Ice a no-brainer.

The supply chain is under momentous pressure to convey vaccines from origin to destination, and collaboration and cooperation on an unprecedented scale will be required to ensure the drug reaches all regions of the world. Advanced technological solutions must be put to good use, and combined with intelligent and rigorous processes to ensure success.

* This is a contributed article and this content does not necessarily represent the views of techtimes.com