Researchers discover a new way to design composite phase change materials that has the ability to store energy as heat. This could start using them in various applications, from heating buildings to powered vehicles.

Efficient Thermal Storage Batteries

Researchers from Texas A&M University have established new foundational design principles for composite phase change materials to store thermal energy quickly. This will simplify the design process and allows a near-optimal composite phase change material to calculate without exhaustive computational fluid dynamic computations or extensive designs.

According to a report from Interesting Engineering, this aims to create a material that strikes a balance between energy density and power density that will allow for efficient storage and fast charging without adding unimportant weight or bulk. It is also possible to make more efficient use of our energy resources through this new design.

While storing energy is not a new process, composites' relatively simple design could be the start of using them in different applications like heating buildings and powered cars. Developing a new design could contribute significant implications in every aspect from how we heat and power our households to designing electric vehicles.

Despite previous studies already exploring the effectiveness of thermal energy storage systems, none have provided insights on improving rate performance, optimizing, and predicting performance compared to the new findings of the researchers from Texas.

Research Funding

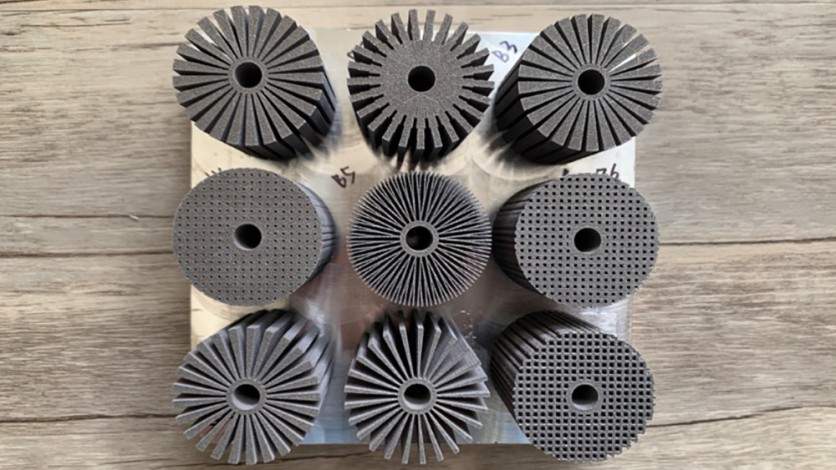

Office of Naval Research funded the team and released it publicly on the Wiley Online Library. It provides a theoretical framework to design and optimize cylindrical composites with three figures of merit. Researchers were able to create a way to design these materials that take into account the heating process, heating storage based on its size, and heat storage based on its weight.

All of these mentioned are considered important factors when designing material for specific purposes, as they can assess the performance of most composite phase change material systems. This will eventually help design future cylindrical composites while accounting for the thermal loads at the same time, specifically for the thermal storage application.

Research Team

Based on a report from TAMU Engineering Department, that the whole research team was led by J. Mike Walker '66 Department of Mechanical Engineering Associate Professor Dr. Jonathan Felts and Former Mechanical Engineering Graduate Student Achutha Tamraoarni in finding a new design to simplify calculations and predict near-optimal structures.

Meanwhile, Department of Materials Science and Engineering Associate Professor Dr. Patrick Shamberge leads the team as the principal investigator, in collaboration with Wm Michael Barnes '64 Department of Industrial and Systems Engineering Associate Professor Dr. Alaa Elwany.

Former doctoral students Alison Hoe (Materials Science Engineering), Chen Zhang (Industrial Systems), and Nathan Malone (Mechanical Engineering) also took part in the discovery.

Related Article : Summer Heat-Storing Tech Can Solve One of the Major Issues in Renewable Energy Sources

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.