Wilson Holdings Group Ltd. Was struggling to eliminate delays caused by job changes, large orders or scheduling demands. With highly flexible, modular software solutions, the company was able to increase efficiency in production by 55%

eProductivity Software (ePS) is a global software company that provides Management Information System (MIS), Enterprise Resource Planning (ERP) and critical business and production software and control systems for the packaging, and corrugated industries.

As part of their packaging software solutions portfolio, eProductivity Software PrintFlow® Dynamic Scheduling software, is designed to help customers improve project management capabilities and provide a holistic view for operations. PrintFlow® has gained an ideal reputation among users in the Greater China region through eProductivity Software collaboration with Wilson Holdings Group Ltd. The Wilson subsidiary Tomato Printing Technology (Dongguan) Ltd. is a leading PrintFlow user.

The company actively promotes new technologies and business models Headquartered in Hong Kong, Wilson has four business sections: trade printing, printing technology sales and service, printing technology finance and general commercial printing.

PrintFlow®, Dynamic Scheduling for Print & Packaging Industries

James Li, CTO of Industry 4.0 at Tomato Printing Technology, knows the system inside out and has a profound experience in its use. Productivity, asset utilization, and customer satisfaction at Tomato Printing greatly improved after it took the lead in adopting PrintFlow®. Li stated that Tomato Printing was only able to roughly estimate the time required for production before the company adopted eProductivity Software PrintFlow®.

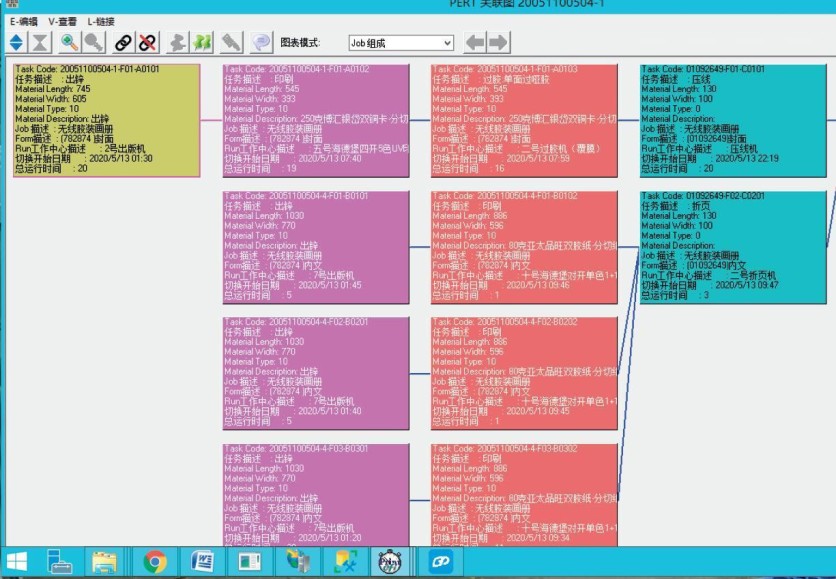

According to Li, the eProductivity Software PrintFlow® system fits the characteristics of printing and packaging businesses. It can estimate the production time needed for each kind of process ahead of time according to the different requirements of the order.

The importance of reasonable scheduling is particularly obvious when dealing with more complex product requirements. Li points out, for example, that there can be a huge variance in the adjustment time needed to set up jobs for different folding processes.

Efficient and automatic production schedulings

Another feature of eProductivity Software PrintFlow is that it makes order transitions smoother. The production scheduling at Tomato Printing, as handled by employees in the past, was unsatisfying during busy hours or with massive orders.

"The data [that PrintFlow® provides] is clear at a glance, which greatly increases efficiency," Li says. "This is all thanks to the different modes of PrintFlow® to simulate production scheduling. It has the ability to prioritize based on factors such as delivery time and cost. The user gets to decide which scheduling mode to choose after simulation."

Li also points out that production scheduling for different processes of all equipment in the plant can be completed within two minutes. "This is very different from the past," he says.

Increasing eProductivity Software workflow presence in Greater China

Wilson is both an agent for and a user of eProductivity Software products. The collaboration between two parties helps in promoting eProductivity Software products in the Greater China region. As one of Asia's leading users of PrintFlow, Tomato Printing started adopting it in phases starting November 2019, implementing the software for various production processes as employees receive training.

Tomato Printing also collaborated with eProductivity Software to create a Chinese version of PrintFlow. This has helped the business development of eProductivity Software in the Greater China region. Li played the biggest part in localizing eProductivity Software PrintFlow, and this has led the system to be more recognized and accepted by Chinese users. He says numerous Wilson clients have wanted to try new systems in the past, but they have been discouraged due to the systems being in English.

With the localization of PrintFlow, the software will be easier for potential users to adopt. eProductivity Software looks forward to working with more businesses in the Greater China region in the future and to moving forward together on the path of smart print and packaging production.

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.