A team of researchers from the University of Waterloo has recently unveiled a groundbreaking development in medical robots.

These scientists have engineered a series of advanced materials set to serve as the foundational components for the next generation of soft medical microrobots. This technological leap opens up possibilities in potentially revolutionizing medical procedures in unimaginable ways.

Researchers from the University of Waterloo have developed sophisticated, intelligent materials that could serve as the foundation for the next generation of soft medical microbots.

Plant-Based Hydrogel for Small Robots

These tiny soft robots have the capacity to perform a wide array of medical procedures, ranging from biopsies to the delicate transport of cells and tissues, all in a minimally invasive manner, according to the research team.

Their unique design enables them to navigate the intricate and fluid environments within the human body, aiming to precisely deliver their cargo, like cells or tissues, to a target position.

These soft robots, measuring only one centimeter in length, possess several remarkable attributes. They are not only biocompatible, ensuring compatibility with biological systems, but they are also non-toxic, further enhancing their suitability for medical applications.

What truly sets them apart, however, is their composition made from advanced hydrogel composites. These composites incorporate sustainable cellulose nanoparticles derived from plants, exemplifying a forward-thinking approach toward materials sourcing.

The hydrogel utilized in this endeavor is particularly noteworthy. It exhibits a unique responsiveness to external chemical stimuli, a feature that enables the controlled alteration of its shape.

This is an essential aspect in the fabrication of functional soft robots. Another distinguishing characteristic of this advanced smart material is its capacity for self-healing.

It allows for an extensive range of robot shapes to be programmed, enabling flexibility in adapting to various medical procedures. Interestingly, the material can be severed and then seamlessly rejoined without the need for adhesives or glue.

This property significantly simplifies the process of configuring different shapes for different medical interventions. Furthermore, the material can be endowed with magnetic properties, a feature that significantly enhances the mobility of these soft robots within the human body.

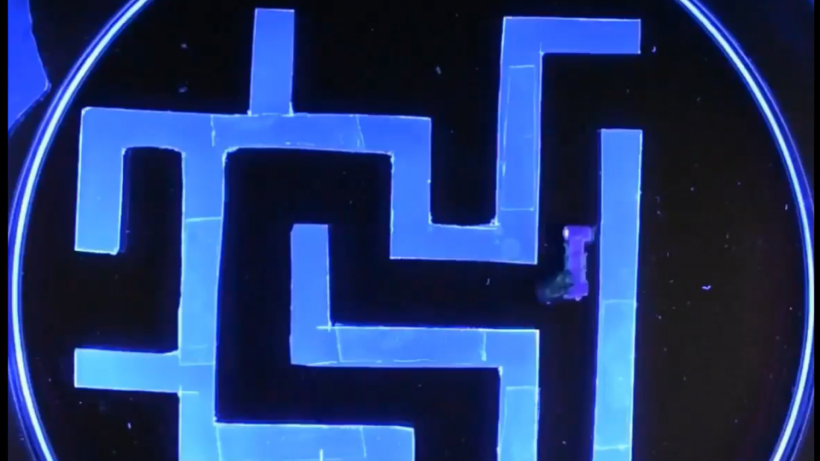

This was demonstrated when researchers successfully navigated the minuscule robot through a maze, effectively showcasing its maneuverability under controlled magnetic guidance.

Read Also: Futuristic Bionic Arm Offers New Hope to Amputees After It Is Merged Seamlessly Into Human Body

'Pushing the Frontiers'

"Chemical engineers play a critical role in pushing the frontiers of medical microrobotics research. Interestingly, tackling the many grand challenges in microrobotics requires the skillset and knowledge chemical engineers possess, including heat and mass transfer, fluid mechanics, reaction engineering, polymers, soft matter science, and biochemical systems. So, we are uniquely positioned to introduce innovative avenues in this emerging field," said Hamed Shahsavan, a professor in the Department of Chemical Engineering.

Looking ahead, the next phase of this research aims to downsize the robot further to submillimeter dimensions. The findings of the research team were published in the journal Nature Communications.

Related Article: Scientists Develop 'Electric Tongue' That Mimics Human Taste Buds, Introducing Emotional Intelligence to AI