In a recent breakthrough, researchers from MIT have introduced an innovative technique involving multi-material 3D printing to create self-heating microfluidic devices.

Developing New Technique

MIT scientists pioneer the creation of 3D-printed self-heating microfluidic devices, offering a potential avenue for the swift development of cost-effective and precise diagnostic tools for various diseases, as suggested by experts.

Interesting Engineering reported that this groundbreaking method holds the potential to swiftly produce cost-effective yet highly accurate tools for detecting a wide range of diseases.

As an illustrative example, the statement highlighted the possibility of integrating these microfluidic components into at-home COVID-19 test kits. In such applications, the devices facilitate chemical reactions, enabling the detection of diseases within minute blood or fluid samples.

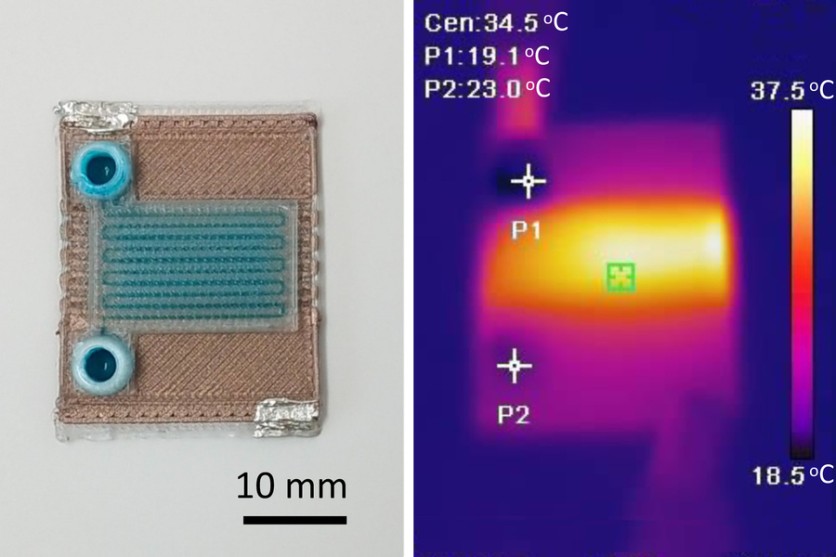

The use of multi-material 3D printing played a crucial role in this innovation. The research team utilized this advanced printing method to create self-heating microfluidic devices with built-in heating elements, all achieved through a single, cost-effective manufacturing process.

MIT has achieved a breakthrough by creating devices designed to precisely heat fluids as they navigate microscopic channels within small-scale apparatuses.

Aiding the Innovation

Underscoring their adaptability and cost-effectiveness, researchers emphasized the ease of customization for these devices, requiring a minimal cost of approximately $2 in materials for their fabrication.

The primary objective of this advancement is to simplify the production of accurate and affordable tools for disease detection, particularly in remote areas facing challenges of limited access to expensive laboratory equipment.

Utilizing multi-material extrusion 3D printing, the research team incorporated two materials into the process: a widely used biodegradable polymer (PLA) and a modified PLA infused with copper nanoparticles.

This modified PLA gains conductivity upon exposure to electricity, leading to the generation of heat.

In a seamless single-step printing procedure, the researchers crafted both the heating resistor and microfluidic channels, enabling fluid flow with concurrent heating. To prevent any potential fluid leakage, they integrated a thin insulating layer between the resistor and microfluidic channels.

Tech Explorist reported that the transformation of the dielectric PLA material due to the introduction of copper nanoparticles is acknowledged by Velásquez-García, who highlights the intriguing alteration in physical properties, a phenomenon not yet fully comprehended but consistently reproducible.

The final device, sized akin to a U.S. quarter, can be manufactured in a matter of minutes. Featuring microfluidic channels measuring 500 micrometers in width and 400 micrometers in height, the device facilitates fluid flow and supports chemical reactions within its microfluidic system.

The PLA material's transparency is crucial, enabling the observation of fluids within the device. Velásquez-García emphasized the necessity of transparency, stating that the ability to observe the process is vital for understanding chemical reactions.

Currently, the researchers have successfully crafted a prototype that heats fluid by four degrees Celsius as it flows. This innovative technique offers the potential for customizing devices to heat fluids in specific patterns or gradients.

Related Article : MIT Researchers Use Synthetic Imagery to Train Machine Learning Models

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.