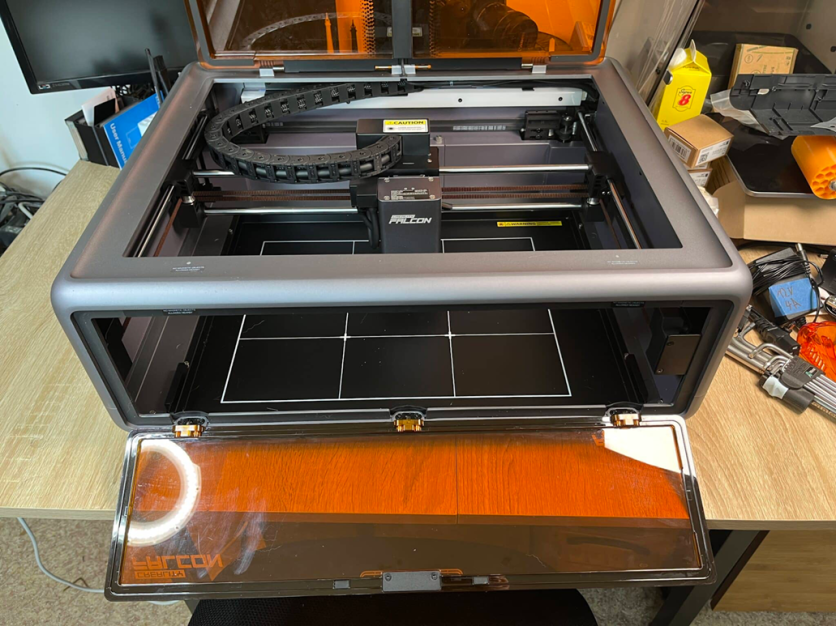

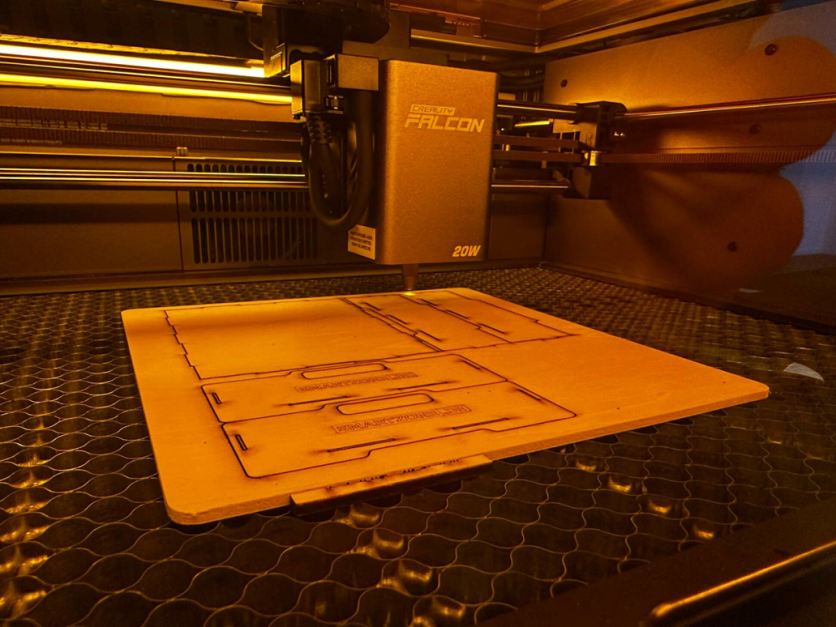

The Creality Falcon A1 Pro arrived well-packaged with protective foam securing every component during shipping. The machine comes nearly fully assembled, requiring only basic cable connections and module installation before first use. The enclosed aluminum construction weighs approximately 18kg and measures 567x468x211mm, fitting comfortably on standard workbenches while feeling substantial and stable.

Unboxing and Initial Setup

Setting up the machine takes less than 30 minutes from unboxing to first cut. The package includes the nearly assembled A1 Pro with pre-installed 20W blue diode laser, air assist pump with automatic control, exhaust tubing, focus calibration tools, a 300x300mm basswood sample, and a complete tool set. The optional 2W infrared laser module ships separately in identical packaging.

The setup process involves connecting the power cable and air assist system, installing exhaust tubing to the right-side port, attaching the touchscreen display, and running initial calibration. Module swapping becomes intuitive after the first attempt, though the 20W blue module requires slightly more effort to secure properly than the infrared unit.

Touch Display Performance

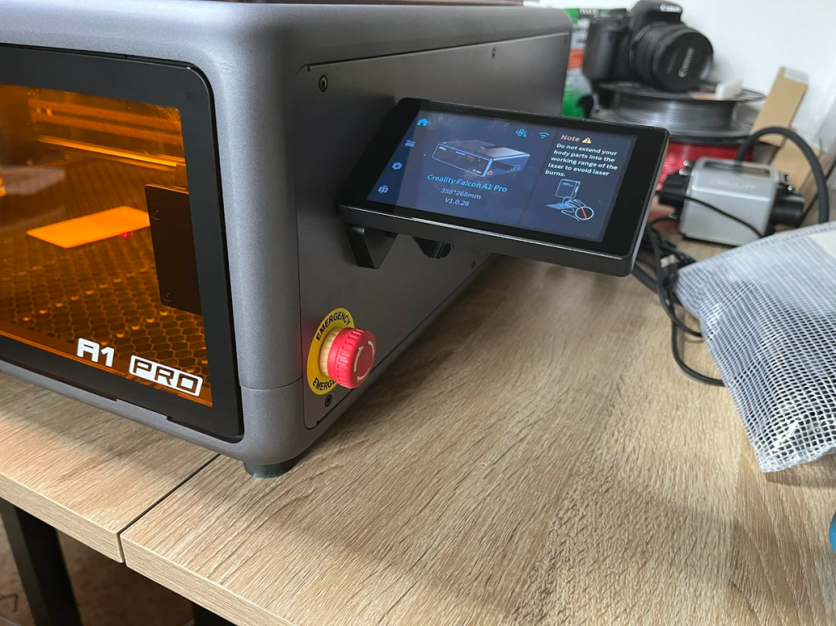

The color touchscreen extends from the right side on a detachable metal arm. The 4.3-inch display provides smartphone-like interface functionality, enabling file browsing from internal memory, USB storage, or cloud accounts. Direct job control happens without computer connection requirements, while one-touch autofocus activation simplifies material setup.

Navigation feels intuitive for smartphone users, with job selection taking 2–3 taps maximum. Parameter adjustments happen through clear menus, while frame preview shows exact cutting boundaries. Progress monitoring displays completion percentage throughout the operation. The display detaches for storage or repositioning, with connectors designed for regular use.

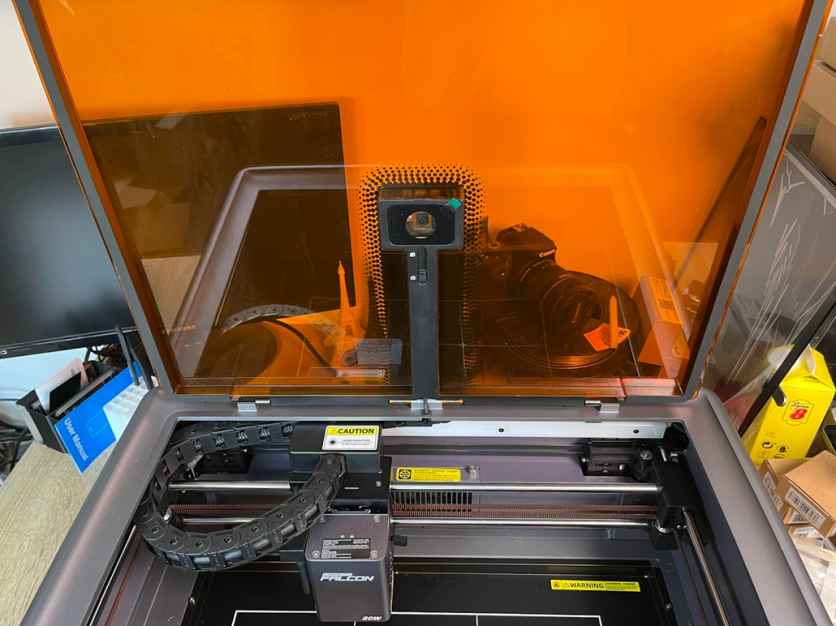

8MP Camera System Testing

Initial setup requires camera calibration using the provided pattern. The process involves placing the calibration sheet on the work surface, following software prompts for corner marking, and completing a 9-point calibration sequence. The entire procedure takes approximately 10 minutes but significantly improves positioning accuracy.

The overhead camera captures the full work area with impressive clarity. Object recognition achieves 80% accuracy on high-contrast line drawings and automatically detects multiple randomly placed workpieces. The trace function converts hand-drawn logos directly to laser files with 90% accuracy for simple geometric shapes, though complex sketches require manual cleanup.

Remote monitoring provides live video streaming with minimal delay. Smartphone notifications alert users to completion or issues, enabling clear progress visibility from other rooms. The system automatically alerts users to potential problems during operation.

Autofocus System Performance

The optical autofocus uses a red helper laser for height measurement, completing activation in three seconds with sub-0.3mm accuracy across material types. The motorized Z-axis eliminates manual height adjustment between projects using different material thicknesses.

However, testing revealed the autofocus consistently sets focus 1–2mm higher than optimal for cutting applications. This positioning works perfectly for engraving but requires manual adjustment using the provided calibration wedge for clean cuts through thicker materials. The Z-axis jogging function allows precise 0.1mm adjustments when needed. Manual focus remains available using the included calibration wedge as a consistent reference point.

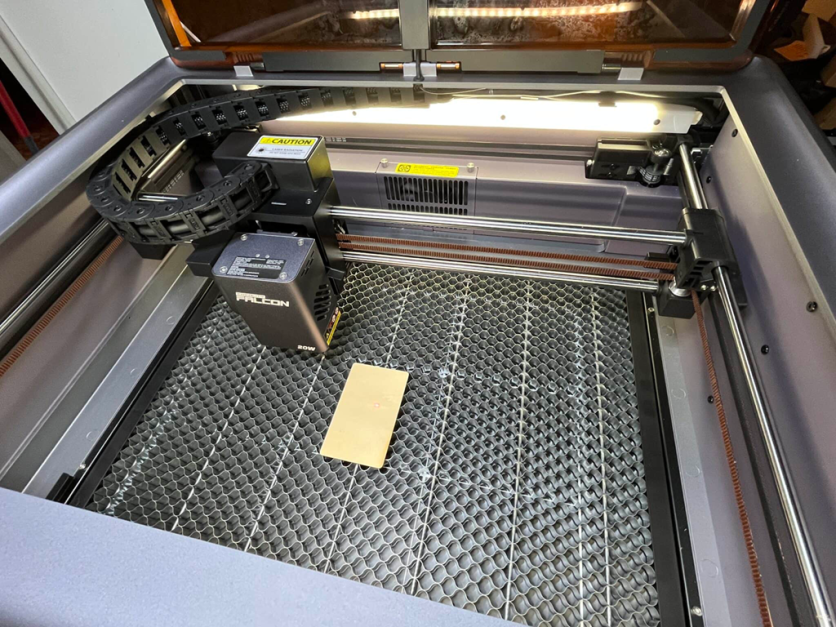

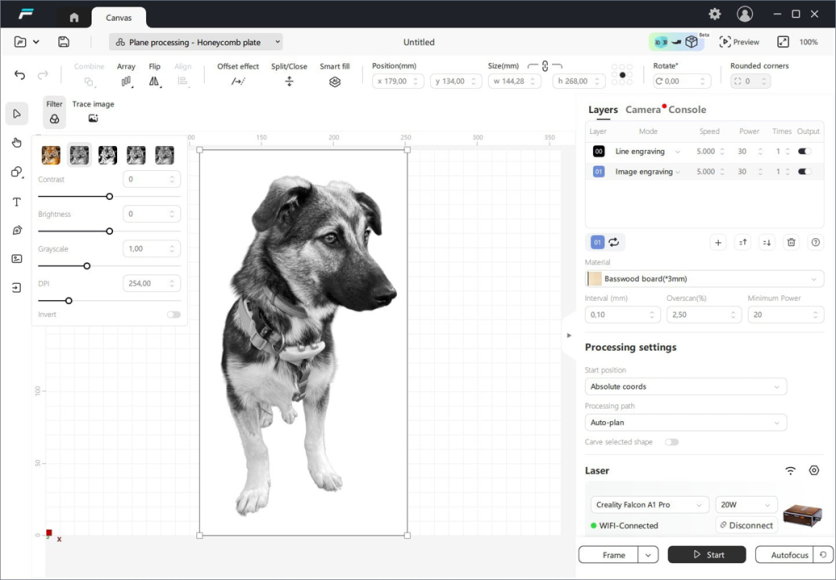

Dual Laser System Testing

The heart of the Creality Falcon A1 Pro lies in its interchangeable laser modules. Testing both the 20W blue diode and 2W infrared systems reveals how this dual-laser approach performs in real workshop conditions. The quick-change mechanism takes under a minute to complete, making material transitions practical for mixed projects that previously required separate machines.

20W Blue Diode Performance

The blue diode laser demonstrates solid performance across organic materials during extensive testing. Three-millimeter basswood cuts cleanly in single passes at 520mm/min with 90% power settings. The 0.08x0.10mm spot size produces detailed engravings with consistent line quality across different wood types.

Photo engraving tests on basswood samples produced impressive results compared to previous laser reviews. Grayscale images maintain detail preservation while achieving smooth tonal transitions. Text down to 8-point sizes remains clearly readable on wood surfaces. Acrylic cutting produces polished edges that rarely require additional finishing, while leather engraving creates rich, permanent markings without burn-through issues.

2W Infrared Module Testing

The infrared module installation takes approximately one minute using the quick-change system. The module feels more secure during installation compared to the 20W blue unit, with positive engagement feedback when properly seated. The 0.03x0.03mm spot size becomes immediately apparent when examining engraved results under magnification.

Aluminum business card engraving produces professional-quality results with crisp text and logo detail, completing in 2–3 minutes per card. Stainless steel jewelry pieces develop deep, permanent engravings that highlight natural metal character without color anodizing effects. Parameter experimentation revealed optimal settings around 100mm/min with 80% power for most metal applications.

Multiple light passes produce better results than single heavy passes, reducing heat buildup that causes inconsistent marking. The infrared module performs best in workshop temperatures between 68–86°F, with noticeable quality degradation outside this range.

Software and App Experience

Falcon Design Space software installation proceeds smoothly on Windows 10 systems. The interface resembles other laser software packages, suggesting shared development resources across manufacturers. WiFi connection works reliably without registration requirements, automatically discovering the laser on local networks.

The camera feed displays properly within the software, showing real-time work area views with minimal lag. File import supports SVG and DXF formats, while export includes gCode and proprietary FDS project files. Material preset databases contain extensive entries for common applications, with advanced parameters accessible through settings menus.

The smartphone app provides basic functionality for simple projects but requires a Creality account for full access. Material databases and clipart libraries remain untranslated from Chinese, limiting practical usefulness for complex design work. The app works better for monitoring than creation due to screen size limitations.

Safety System Validation

The enclosed design contains laser radiation effectively during normal operation. Deliberate testing with door sensors confirmed immediate shutdown when panels open during laser operation. The emergency stop button provides instant power cutoff with tactile feedback that inspires confidence during use.

Flame detection testing involved placing easily ignitable materials in the laser path. The dual detection system responded within one second, shutting down the laser and activating smartphone notifications simultaneously. Built-in air filtration handles smoke removal adequately for wood and acrylic projects, though leather and fabric processing benefit from additional ventilation.

Real-World Project Testing

Daily use testing included various projects typical of small workshop environments. Custom signage on 3mm wood completed in 15–20 minutes with detailed engraving and clean cut edges. Business card production on aluminum averaged 2–3 minutes per card with professional results suitable for commercial sale.

Jewelry marking on stainless steel pendants required parameter adjustment, but achieved consistent results across production runs. The infrared laser created tactile engravings with sufficient depth for permanent marking applications. Mixed-material projects demonstrated the system's primary advantage, combining engraved wood bases with marked metal plaques without machine changes or workflow interruption.

Performance Limitations and Value Assessment

Cutting performance rates as adequate rather than exceptional for a 20W system. Four-millimeter hardwood requires multiple passes or reduced speeds for complete penetration. The system excels at engraving applications but should not be considered primarily a cutting tool for thick materials.

The complete dual-laser system costs substantially more than base unit pricing suggests. The infrared module adds approximately $500 to the total investment, making the system competitive with premium single-laser alternatives. However, separate machines for diode and infrared applications would cost significantly more while requiring additional workshop space.

Small businesses can justify the investment through expanded service offerings unavailable to single-laser competitors. Metal marking commands premium pricing in custom product markets, while mixed-material capabilities create unique value propositions. Educational institutions benefit from comprehensive material coverage and robust safety features for student use.

Final Assessment

The Creality Falcon A1 Pro delivers genuine innovation in desktop laser engraving through practical dual-laser implementation. While individual laser performance rates as good rather than exceptional, the combination creates capabilities previously unavailable in this price category. Build quality and safety implementation provide confidence for residential use, while software functionality meets most requirements despite documentation limitations.

The machine succeeds for experienced makers comfortable with laser fundamentals who want metalworking capabilities without industrial equipment costs. The enclosed design, smart features, and material versatility represent meaningful progress in desktop fabrication technology that justifies investment through expanded project possibilities.

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.