Tesla has a massive die-cast machine that operates on its factories to produce electric vehicle parts, including that of the chassis, doors, and other metal body parts of its outputs. Elon Musk has revealed that there are both advantages and disadvantages to owning it but has mostly leaned on what it brings for the clean energy company.

Tesla Owns the World's Largest Die Cast Machine

No, Tesla is not those specialty and luxury car brands like Pagani or Lamborghini that makes every component in the vehicle by the hands of its engineers and also assembles it without the use of machines. Tesla is more of a consumer car brand, aiming to make electric vehicles available to the masses and produce its EVs for everyone.

It does not mean that Tesla and Elon Musk has skimped out on the details of its electric vehicle, and it does not sacrifice the quality delivered by the EV for its customers. The use of die-cast was initially thought for the Tesla Cybertruck only, especially as the company purchased a massive one earlier this year and is said to be the "final piece of the puzzle."

Read Also : Elon Musk Confirms SpaceX Ocean Spaceport Deimos Under Construction for Starship Launch Next Year

Tesla's Die Cast Machine, As Characterized by Elon Musk

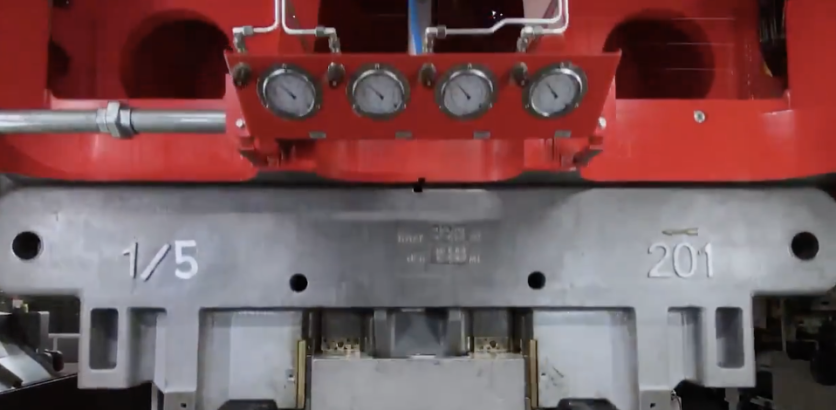

A die-cast machine is like a press that forms the metal around a certain cast, containing all the details that the vehicle needs. All the nooks and crannies would be placed once assembled. Tesla is known to rely mostly on technology, and one of its top techs is the use of a die-cast machine for all its vehicle needs.

According to Tesla CEO (@elonmusk), making these die-cast machines work is one of the challenges the company has faced and is still facing, especially as the massive technology can either be a hit or miss. However, Musk categorizes it as something "revolutionary" for a vehicle's body design and production, alongside other reasons.

These reasons include other factors surrounding a vehicle element, with its body being lighter, tighter, and have a better NVH (noise, vibration, harshness), alongside being a cheaper unit to produce, a lower CAPEX, and higher precision in making one.

Making this work has been / still is super difficult, but it’s a revolution in car body design & production – lighter, tighter, better NVH, higher precision, lower capex, lower unit cost

— Elon Musk (@elonmusk) May 31, 2021

Tesla (@Tesla) has showcased a video of the actual die cast machine of Tesla which shows how it works in a factory and how it brings a car chassis to its form for production.

Disadvantages of Die Casts?

There are also disadvantages of die-cast machines, but Tesla and Musk did not go into details of these, only saying that they are a challenge to operate and use on their specific mileage. However, it is known that machines can malfunction and create wrong press or "casts" of the metal, hence the rejects or factory defects that may or may not reach the buyer's hands.

Related Article : Is Tesla Cybertruck Better Than Ford F-150? Here's an Advanced Spec-by-Spec Comparison

This article is owned by Tech Times

Written by Isaiah Richard

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.