North American companies have employed more robots in 2022 than ever before due to labor shortages. These robots were particularly used for new electric vehicle and battery facilities that are under construction, according to a report by Reuters.

However, it seems that the demand for robots has slowed down near the close of the year, raising concerns about how robust 2023 will be amid increasing interest rates and changing household spending habits.

A3's 2022 Data

According to data gathered by the Association for Advancing Automation, also known as A3, businesses from the United States, Canada, Mexico, and other countries bought over 44,100 robots in 2022, an 11% increase from the previous year and a new record as well.

The data indicates that the overall worth of those machines was $2.38 billion, which is a significant 18% increase from 2021.

According to Jeff Burnstein, president of A3, labor shortage could be attributed to the new record. Burnstein noted that orders showed a noticeable slowdown at the end of the year, raising concerns about how robot orders may develop in 2023.

According to him, the orders drop-off in some segments was likely caused by a change in customer behavior from the pandemic.

"You saw companies like Amazon put a pause on building new warehouses, which means they probably canceled or delayed purchases of new automation," Burnstein said in a statement with AP.

The results from last year may have been skewed by issues with the supply chain.

Burnstein said that customers placed supplemental orders with robot manufacturers during the COVID-19 pandemic to ensure they would obtain at least some of what they needed.

Read also : How Engie's Startup Solar AI Technologies Uses Affordable Models To Make Solar Energy Accessible

Robot Orders From Automakers and Suppliers

More than half of the orders placed in the previous year came from automakers and their suppliers, according to A3's data.

Atlas Public Policy, a US-based research organization that collaborates with automakers and environmental organizations, said that new plants for electric vehicles and batteries were introduced since the start of 2021 at a cost of $160 billion.

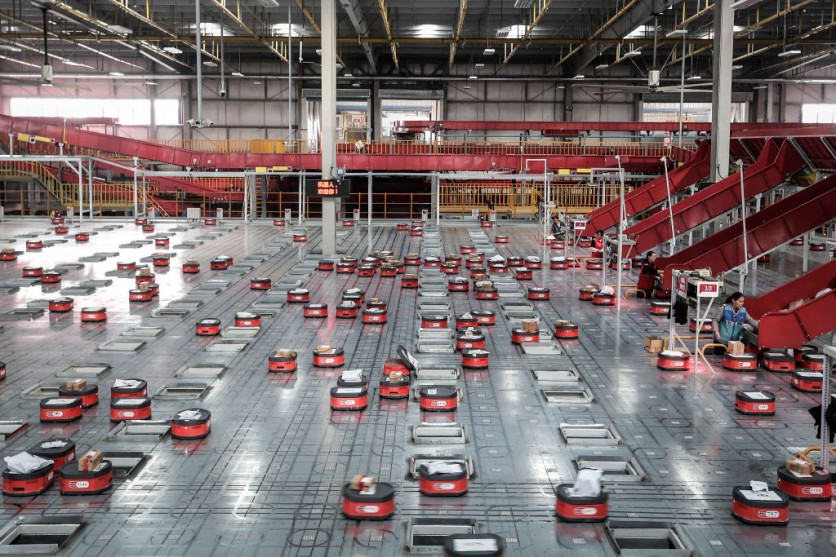

The majority of the robots ordered in 2022 will be utilized for material handling, a broad category that encompasses all kinds of product movement and handling in warehouses and factories.

For example, the expansive plant of Closure Systems International Inc. in Crawfordsville, Indiana, has automated the task of packing and sealing boxes at the end of the manufacturing line. The business manufactures closures for items such as soda bottles and other food packages.

Related Article : How Engie's Startup Solar AI Technologies Uses Affordable Models To Make Solar Energy Accessible

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.