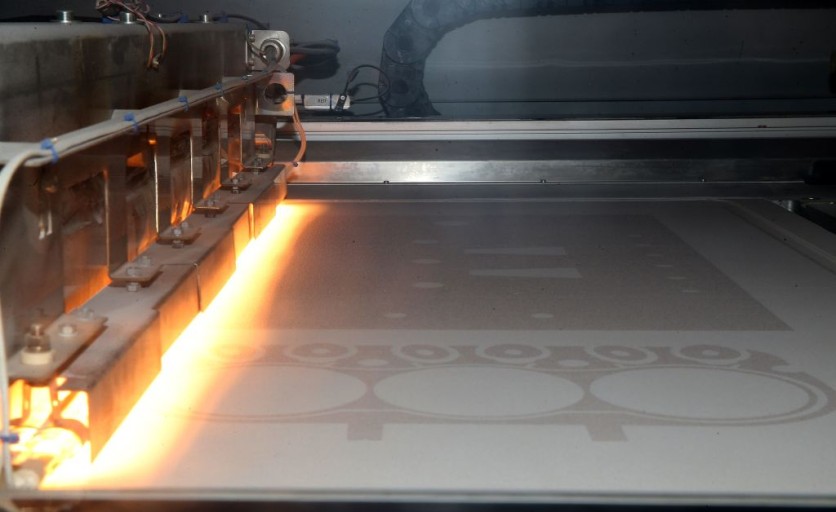

Arizona-based company, Rosotics, has announced the launch of its revolutionary "rapid induction printing" technology that aims to transform large-scale 3D metal printing.

The approach, developed by Rosotics' founder and CEO, Christian LaRosa, can create large parts at high speeds, significantly cutting costs and improving safety and energy efficiency, as per a report from New Atlas.

Rosotics' Alternative Process

Traditional additive metal manufacturing involves using lasers to heat and melt powdered metal feedstocks, which can be expensive and hazardous. Rosotics' alternative process uses induction to heat metal inductively, a highly efficient and natural way of 3D printing metal.

The company's new printing head, called Mantis, delivers heat to the metal inductively, making the process cheaper and quicker, and able to produce parts big enough for structural use in aircraft and rockets.

The feedstock does not have to be ferromagnetic, meaning a wide range of metals can be used, and the printer can handle wires between 1-10 mm in diameter, which can be scaled upwards if necessary.

Rosotics has extensively tested its new approach with steel and aluminum, and the company claims that it can handle most metals available in wire form.

The printer can be powered by a 240-volt outlet similar to those seen in common warehouse settings. LaRosa claims that Rosotics has created novel methods for inductively heating feedstocks that make use of ground-breaking metallurgical science techniques.

As a result, the printer is capable of handling a wide range of materials, including titanium, which is regarded as a workable material.

The company is currently concentrating on cupronickel since it offers good mechanical performance in some applications, according to New Atlas.

Read Also : Lockheed Martin Partners With 3D Printing Company for Research Expansion of Metal Additive Parts

Revolutionize the 3D Printing Market

The new approach from Rosotics might revolutionize the 3D printing market. Its induction-based method of 3D printing may work with a variety of metals and is substantially faster, cheaper, and safer than conventional laser-based methods.

The aerospace and automotive industries stand to gain significantly from the capacity to produce massive parts quickly. With a lot of testing already completed, Rosotics seems prepared to advance and completely transform the metal 3D printing market.

"Our system is very well suited for structural applications, say the structure of a rocket, or the structure of a tank," LaRosa said in a statement with New Atlas.

"Any kind of structural part that aerospace would demand, our system can do it. But it's designed to branch out to heavy industry at large. Energy, marine construction, we can serve these applications very well."

Related Article : 'Chameleon Robots:' These Robots Can Change Colors and Mimic Their Surroundings Through 3D Printing

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.