The Earth's gravity has always been a huge restriction to building the largest and most ambitious structures. But scientists are already making strides to take down this barrier by doing so in orbit.

MIT scientists have teamed up with NASA to create space test parts in accordance with a research initiative that focuses on paving the possibilities of microgravity manufacturing.

The novel procedure entails filling a silicone skin with liquid resin to replicate an object. However, it is worth noting that this process does not work on Earth because of gravity.

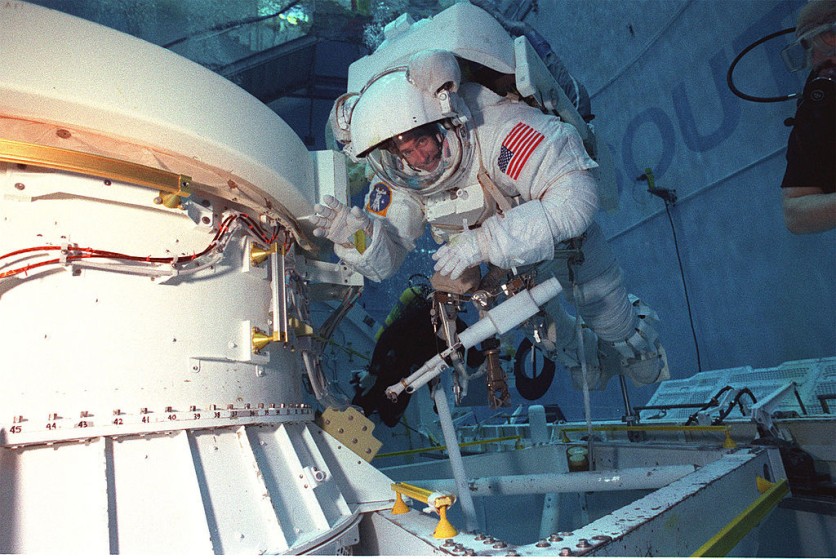

Hence, MIT scientists are employing this manufacturing method aboard the International Space Station (ISS).

Similar to Balloons

As reported first by PopSci, MIT scientists are now using a metal box that is around the size of a desktop PC tower. A nozzle inside is assisting in the construction of tiny test parts that are impossible to manufacture on Earth.

MIT engineer Martin Nisser said that the process is similar to balloons but instead of filling them with air, they are filled with resin. The materials used are not that hard to access since the skin and resin are off-the-shelf products.

It is worth noting that ultraviolet (UV) light is sensitive to the resin. A UV flash causes the balloons to emit light that passes through their skin and covers the resin. It hardens into a solid structure as it dries and stiffens.

Astronauts can remove the skin and reveal the internal component once the process is complete.

All of this takes place within the box, which was launched on November 23 and is intended to stay on the ISS for 45 days. If all goes well, the ISS will return some experimental components to Earth for the MIT scientists to test.

Read Also : MIT Says NASA James Webb May Be Too Advanced; Experts Claim Data Misinterpretation Might Happen

Future Uses

The team will conduct a follow-up experiment aboard the ISS to construct more complicated parts if they are satisfied with the results. They also want to carry out an experiment by producing pieces outside the space station.

The advantage of constructing components like this in orbit is that the planet's gravity, the hugest stressor, is no longer a constraint in building structures.

The scientists envision a future where astronauts will not require sending a part from Earth to repair any necessary objects in space, rather, they will have to rely on filling up a silicone skin with resin to replicate that component.

However, the researchers are also considering the long run. They believe that by producing extremely long parts in space, they will be able to build larger, and more ambitious structures such as habitats for spacecraft.

They may also serve as the structural framework for radiators that prevent a habitat from becoming too warm.

According to Nisser, the ultimate goal of this experiment is to make this novel manufacturing procedure accessible to other researchers.

Related Article : MIT Mini Cheetah Robot Speed Enhancement Made Possible, Thanks to New Simulation Training-Similar to 'Matrix?'

ⓒ 2026 TECHTIMES.com All rights reserved. Do not reproduce without permission.